Tungsten Plastic

Tungsten Plastic Introduction

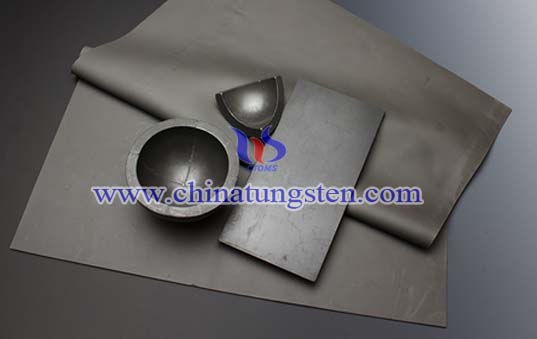

As the properties tungsten plastic, uses of tungsten plastic dates back to several years ago. Tungsten plastic makes an important contribution in our daily life, especially in radiation shielding areas. It is filled up plastic of halogen-free with tungsten powder, it has the advantage of tungsten such as good radiation resistance, high density, etc. through extrusion technology, and adding plastic in tungsten, it also has advantages of plastic, such as lead-free, high flexibility and can be easily machined into various of shapes, without using ROHS materials, low cost, higher ductility. Instead of lead tungsten plastic is a better material to make radiation shielding, because plastic tungsten is non-toxic and environmentally friendly material.

Applications of Tungsten Plastic

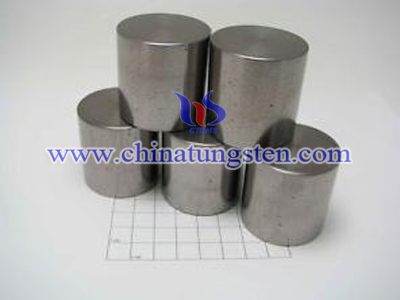

Plastic tungsten is used when efforts accelerated to replace lead for radiation-shielding applications. Tungsten plastic product is one of our leading products. Our thermoplastic tungsten composite bands are cut from tubes extruded in a single process, which can provide cost savings and shorten lead times, our plastic tungsten offers outstanding rationality and can be thermally bonded to shafts for greater quality assurance. Good corrosion resistance and good surface finishing of tungsten plastic products are critical. Tungsten loadings range from 65% to 80% by weight to meet radiopacity requirements. As these properties, tungsten plastic tubes are widely used in industry areas.

Tungsten plastic is widely used in radiation shielding, as it has the properties of tungsten such as high radiation absorption, high density, non-toxic, environmental friendly, etc. Tungsten plastic is the best material to make into radiation shielding which is widely used in medical areas as well as other industry areas.